Do you know the factors to consider in designing and operating an efficient warehouse? This quick and easy guide has you covered if you don’t. Essentially, there are several principles to think about for a smooth-running supply chain. You should aim to get things right from the start to ensure higher productivity.

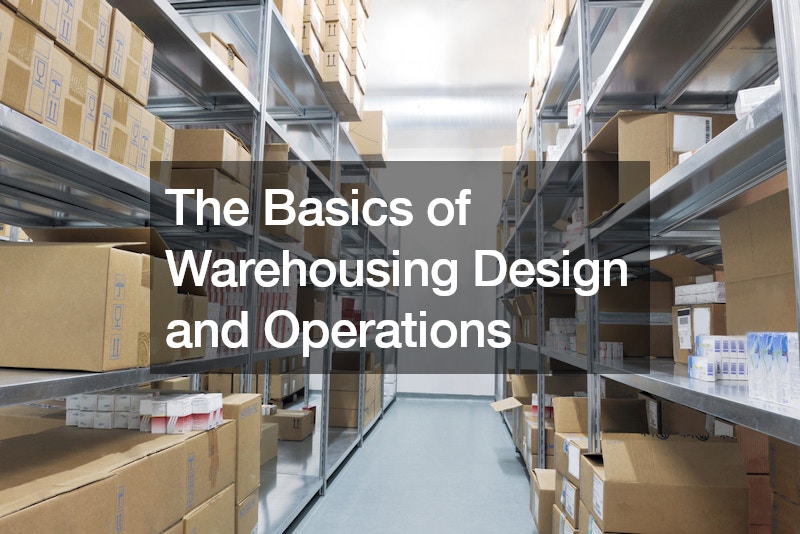

One of the fundamentals to focus on is layout planning. You want to ensure the space can accommodate as many goods as possible.

That’s easily achievable with strategic design. A well-planned warehouse also ensures a logical flow of products to minimize traffic crossovers. This means there will be designated areas for different activities like receiving and packing or shipping.

After considering the layout, think about racking and storage solutions. You might need to research the appropriate equipment for storing the goods you intend to have. Some of the available solutions for storing products include pallet racks for bulk items, shelves for smaller goods, and automated storage and retrieval systems (AS/RS) for high-demand items.

Another must-consider factor is warehousing technology. There are different technologies available today, ranging from warehouse management systems (WMS) to radio-frequency identification (RFID) and automated material handling equipment. Each tech has its application, but they all aim to improve efficiency and accuracy.

So, think about these design and operational factors early on. They can help you create a warehousing environment that maximizes storage and simplifies workflows. Additionally, they can keep the supply chain running smoothly for a successful business.

.